factory focus

Somelos

We work with Somelos to produce our brushed cotton and checked fabrics.

The Somelos factory was founded in 1958, originally focusing on the production of cotton yarns, but later added weaving and dying to the services they provide, becoming a fully vertical supplier.

All of their fabrics and dyes are Oekotex certified.

All these services are located in a private industrial park, with an area of 300,000 square meters, which includes various social infrastructures for employees.

Somelos looks to the future by developing its activity in demanding and constantly evolving business areas, in order to continue to serve its customers as it has done for the past 50 years.

Stages Of Production

Raw Cotton Sourcing

Somelos source their organic cotton from the best farms in the world located in Egypt and the United States.

On arrival at the factory the raw cotton is inspected for debris such as twigs and plant matter.

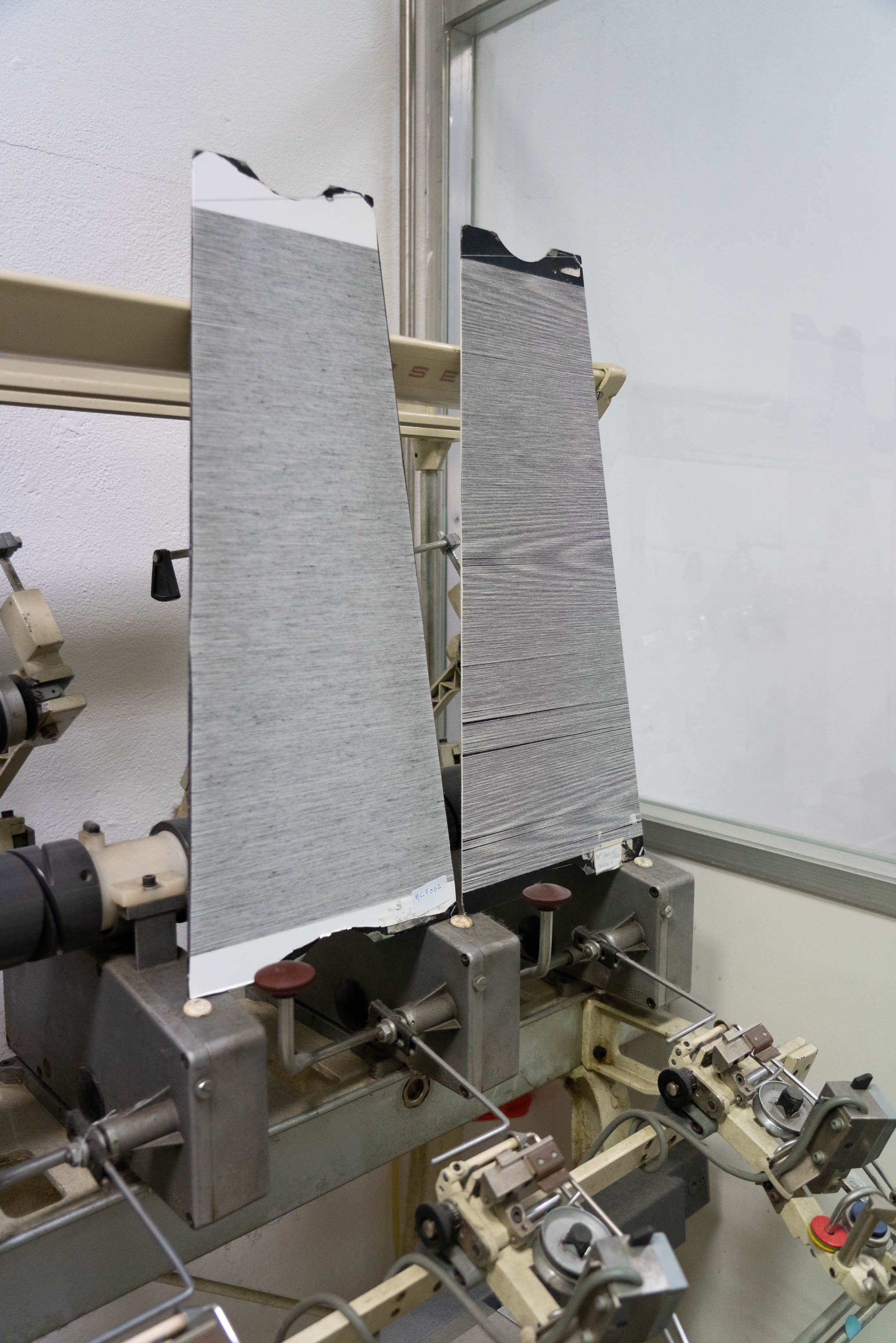

Testing

Somelos undertake numerous tests on all the raw cotton from their farmers across the world.

These fibre tests include: length, strength, colour grading and uniformity (pictured above).

Carding

The raw cotton is combed between 'cards' set with multiple wire teeth, to clean and strengthen the fibres.

Carding accomplishes the separation and disentanglement of fibres, alignment of fibres and removal of short fibres

Ring Spinning

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn.

Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action